Why is it important to correctly size a domestic hot water system?

Accurately sizing hot water systems helps to ensure the system meets demand in the most effective way, as well as protecting our planet and its resources through only providing the volume of hot water that is required. Demand placed on hot water systems will change as population levels rise and consumer behaviour changes along with advances in technology. Plus, there is an increase in the scarcity of water and other precious resources. If correctly sized, a domestic hot water system should run more efficiently, resulting in reduced heat losses, reduced energy use, and a lower carbon footprint.

What guides and methods are currently used for sizing domestic hot water systems?

Engineers use the most up to date version of sizing standards from official bodies to size hot water systems. These include:

CIBSE Guide G:2014 Public Health Engineering

Originally published in 2014, prior to this edition the CIBSE guide used demand units but it’s now recommended to use this newer guidance.

IOP Plumbing Services Design Guide

Widely used, this guide enables engineers to select pipe sizes based on pressure loss per metre run of pipe, and the resultant water velocity.

British Standards BS 8558:2015

The previous standard BS 6700 has been replaced by BS 8558 and BS 806 which both use demand unit calculations but are, in reality, pipe sizing guides.

BS EN 806-3:2006

In this European harmonised standard Loading Units are lower (the largest is 5000 = 9 litres per second) and no ranges are provided for peak and non-peak use.

Each gives different information based on demand or load units (LUs) and steer the engineer towards a static system design.

What are loading units?

The most commonly used guides rely on loading units (LUs). This method of estimating the load on a plumbing system dates back to the 1960s. It was devised by the then-president of the IOP Harry Howick and based on the ‘Methods of Estimating Loads in Plumbing Systems’ by US author Roy. B. Hunter.

This assigns a discharge value to plumbing fixture outlets compared to a base appliance of 1 LU. Using tables of data, design guides - such as the IOP and BS 8558:2015 – provide base data for simultaneous demand for a base appliance (e.g. a hand basin with a frequency of 1.2L/ second) with all other appliances having a higher value.

Optimum pipe size is calculated by gauging frequency of use, with time difference between uses assigned to Low, Medium, and High, taking into consideration pressure at the inlet to the building to ensure velocity and to guard against pressure loss.

What are the issues with the existing methods for sizing domestic hot water systems?

The current standards for sizing demand don’t provide the flexibility required to design efficient future-focused systems. Research has shown that this static approach leads to overestimating demand and the inefficiencies that accompany it.

1. The approach doesn’t allow for significant improvements in building design, insulation, and heat efficiency that have been made since creation of the model.

2. The model doesn’t consider seasonal changes in building usage - for example in the case of a UK hotel experiencing high capacity in the summer and low off-peak occupancy.

3. These guides haven’t kept up with advances and developments in technology and the increasing prevalence of green tech to reduce carbon emissions.

What data is there to back this up?

Independent technical papers by Northumbria University[1] and Heriot Watt University[2] (the LUNA study) have compared calculation results from the guides with actual results in real-world scenarios. They show how oversizing occurs when using loading units (LUs) and look at the impacts this oversizing can have.

They show us that these DHW sizing methods overestimate peak water volume flow rates which can result in:

· A larger demand footprint than necessary – leading to oversized pipes, pumps, and ancillaries

· Decreased efficiency across the system

· Stagnant water due to increased length of time for water to flow through the system, leading to a higher risk of legionella

· Higher cost of larger components

![]()

[1] Tindall, Jess and Pendle, Jamie (2017) A comparison of UK domestic water services sizing methods with each other and with empirical data. Building Services Engineering Research and Technology, 38 (6). pp. 635-649. ISSN 0143-6244

[2] Jack, Lynne & Patidar, S. & Wickramasinghe, Achala. (2017). ASSESSMENT OF LOADING UNITS METHOD FOR SIZING DOMESTIC HOT & COLD WATER SERVICES

What is the best way to accurately size domestic hot water systems?

Behaviours change and building use flexes over time so it is impossible to be 100% accurate in sizing demand. Sizing estimates need to be based on a certain selection criterion from the outset, and a design created that is flexible enough to accommodate fluctuations in demand without unnecessary overheads. The ACV approach creates a dynamic design to allow for this flexibility.

To make an accurate assessment designers should always consider the unique elements of every job, knowing the system and setting the criteria, specifically:

Application type

· Large Storage – where the DHW peak demand must be met in a very short period of time then storage capacity has to be the primary concern. Recovery rate is selected to reheat the storage ‘dump load’ in a specified period of time before a repeat of the ‘dump load’. Examples are commercial and industrial processes, accommodation blocks, and showering facilities for e.g. football or rugby clubs

ACV tank-in-tank Products for large storage projects:

- ACV HeatMaster gas fired with integral storage, combined with ACV Smart cylinder

- ACV large storage calorifiers combined with HeatMaster/ Prestige boilers

· Semi-instantaneous – where DHW demand is relatively constant with little storage requirement as hot water is provided continuously over extended periods of time. Recovery is primary, storage is secondary. Examples include factory wash down processes, industrial kitchens, and some showering applications.

· ACV tank-in-tank products for semi-instantaneous projects:

- ACV WaterMaster gas fired water heater

- ACV high recovery tank-in-tank calorifier

· Balanced loads – where the DHW demand varies from 30 minutes to approximately 2 hours. In this case, storage and recovery are equally important with sizing focused on demand per hour while making an allowance for simultaneous demands.

· ACV tank-in-tank products for balanced load projects

- ACV HeatMaster gas fired with integral storage

- ACV high recovery tank-in-tank calorifier

Fittings

· The number, type, and flow rates of the outlets being served. For example, how many showers and what type of shower they are.

People

· The number of people needs to be taken into account because this is where the demand comes from. Consider whether that will change over time.

Time

· It is critical to understand the peak TIME period & how it influences the DHW Sizing. The peak period can be any length of time and can be intensive, continuous, or normal

Using these criteria to design a dynamic system to meet base, fluctuations, and peak requirements will deliver a DHW system that is difficult to undersize and is fit for purpose, efficient, and scalable.

What are the benefits of a dynamic DHW system?

The ACV dynamic system is designed with:

· Relatively low storage (compared to the traditional sizing approach)

· A preference for ‘always hot’

· Faster reheat time (10 – 30 minute)

These dynamic, flexible systems respond far better to variations of demand, use less energy and waste less water, making them a more responsible, sustainable design. Equally, dynamic systems have a far smaller footprint, using less gas and pipework, and smaller, more efficient cylinders. Future requirements and increases in demand can also be met by the ability to extend that a dynamic design gives you.

What is an example of a dynamic system design?

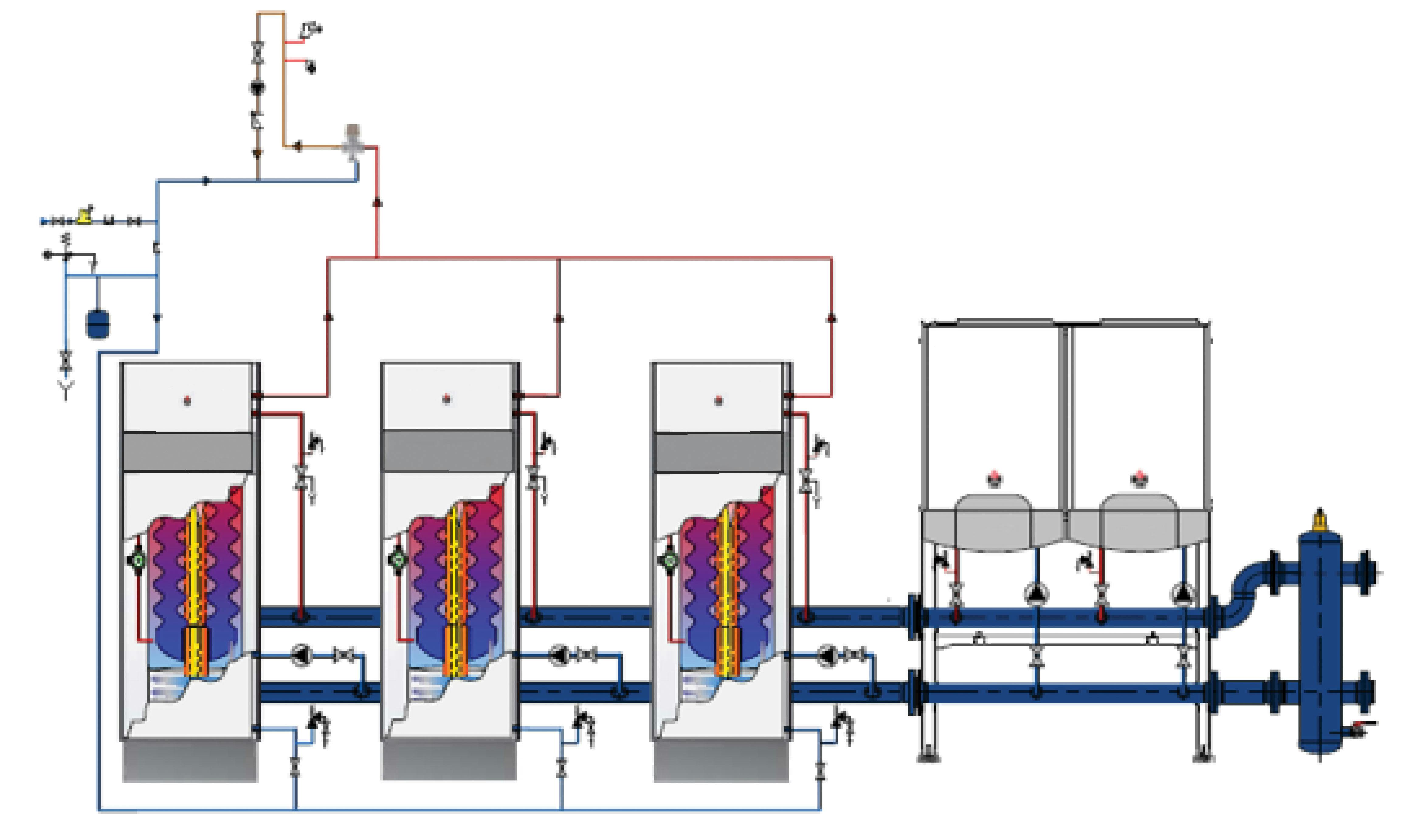

Using a dynamic approach to sizing a DHW system, you can create a system arranging ACV HeatMasters in series to provide 500kW heating, 3000 l of hot sanitary water along with 570 litres of storage.

In this arrangement, we have 4,914 litres of DHW at 60ºC in an hour, with less than 600 litres of stored hot water using a significantly smaller footprint. This provides more than 50% duty standby on the DHW too, compared with a traditionally sized system.

There is no wasted energy as we are only heating the water needed and a significantly reduced risk of legionella as there is less storage and higher temperatures. Installing HeatMasters on almost any project will save plant room space, reduce overall system kW, and possibly allow for smaller pipes.

With the developments in technology and system design that are available to us now, there is far greater scope to accurately size and design a dynamic, futureproofed DHW system that delivers efficiency and sustainability for now and years to come.

Take a look at Archimedes to help you design your approach to hot water with ACV products.