What is an unvented hot water system?

In traditional vented hot water systems, cylinders store and heat water that is fed from a tank in the loft. Unvented systems, however, use an unvented hot water cylinder fed from the cold water mains. This closed cylinder maintains its pressure from an incoming mains water supply. Unvented cylinders account for a larger proportion of the market. According to market statistics (January 2021) from the hot water association, approximately 72% of all 50-500 litre cylinders sold were mains pressured/unvented type.

Because unvented systems are closed - and have no way to vent the pressure that can build up as the water heats - they will require additional equipment such as expansion vessels. Expansion vessels have an important part to play in an unvented system to prevent damage and accommodate expanding water.

What are the benefits of an unvented system?

Unvented systems save space because they don’t need a separate cold water tank and the associated pipework that links it across the system.

Unvented systems therefore have a greater capacity for large commercial or residential properties to deliver hot water across complex designs and longer pipe runs.

Unvented systems usually have stronger water pressure than tank fed systems as the pressure comes from the mains feed, and water outlets like taps and showers give a better performance. There is far less risk of unvented systems freezing in winter and they are less likely to become contaminated – something that can happen with vented systems due to the use of an open tank.

What is an unvented kit?

When installing an ACV tank-in-tank cylinder or water heater in an unvented system you need specific components to make sure that it meets the legal safety requirements laid out in Building Regulations Approved Document G, section 3. An unvented kit contains the additional components you need to safely install your unvented system. These are specified with the cylinder (often incorporated as part of the product package) and usually include an appropriately sized expansion vessel along with the required additional safety valves, fittings and thermostats.

Which unvented kits are available from ACV?

ACV offer a large range of unvented kits that are bespoke to our products. With some products the unvented kit comes as part of the product package. Please refer to the product pages or your local contact for more details.

What are expansion vessels?

Expansion vessels are essential in any pressurised heating system and are likely to be present in an unvented hot water system. Without an appropriately sized expansion vessel the components of a closed water system are at risk of becoming damaged by changes in pressure.

Expansion vessels - also known as hydraulic accumulators or expansion tanks – are usually located in or near the boiler/water heater but this will depend on your system design.

How do expansion vessels work?

Expansion vessels contain air or an inert gas such as nitrogen – as well as water from the system - separated by a membrane that is either a rubber bag or bladder, or a rubber sheet or diaphragm. Water in the expansion vessel expands as the cold, pressurised mains water is heated. As it does, the air within the vessel is compressed to absorb the increased volume, managing the impact of the pressure increase. As the water cools, its volume decreases, and the water level drops again.

What are flow through expansion vessels?

Slow moving water in a closed, unvented system can create prime points of risk for the growth of bacteria such as Legionella (which can cause serious illnesses and is potentially fatal). Standard expansion vessels can be susceptible to being such a point of risk, particularly when systems are left unused for long periods or pressure remains constant over time.

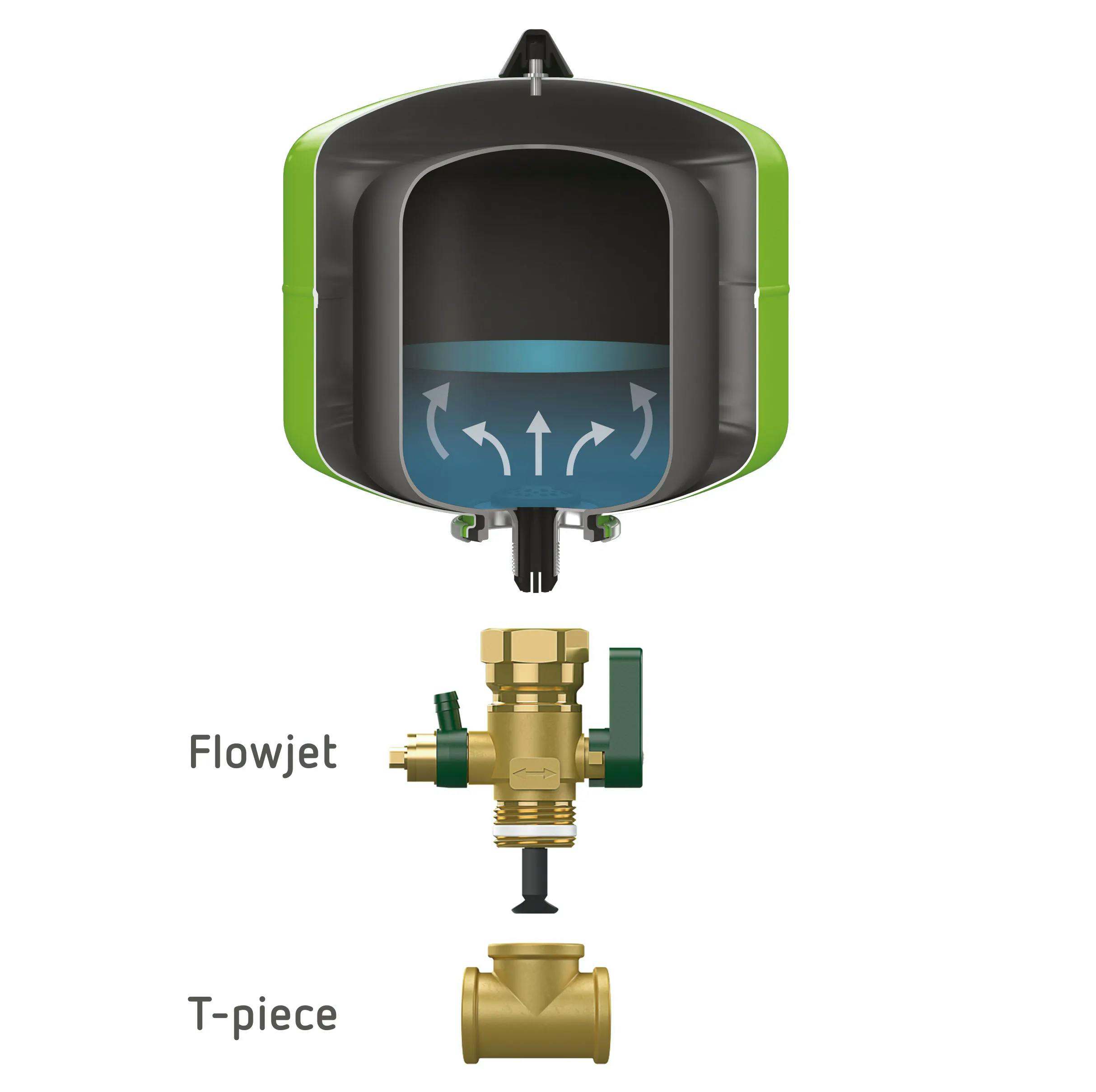

Flow through expansion vessels reduce this risk by using a Flowjet valve to force water through the expansion vessel. The Flowjet valve diverts part of the water flow from the system supply into the vessel. Because water is continually moving through the vessel, this prevents water stagnation and reduces the risk of harmful bacteria such as Legionella from forming on the rubber lining of the vessel.

The ACV unvented kit Systempak 3FT (flowthrough type) includes a Flowjet valve that is attached to the bottom of the expansion vessel and - along with the T piece supplied with the larger model - reduces the need for pipework out of the top and allows for the same movement of water. The Flowjet valve means that vessels can be more easily drained, bypassed or isolated for removal or replacement.

What are the benefits of flow through expansion vessels for unvented kits?

In usual day-to-day operation an expansion vessel will exchange water with the system by regularly partially emptying and refilling. Sometimes, however, expansion vessels can suffer from low flow rates which can lead to stagnant water remaining within the vessel. At this point they become points of risk of bacterial growth. This is particularly true if the system lies unused, or the pressure and temperature remain steady over a period of time. Installing a flowthrough expansion vessel will keep the water moving, even with low flow rates.

Flow through expansion vessels reduce the risk of bacterial growth in a closed, pressurised system. They can also reduce the amount of pipework required and give the user more flexibility for maintenance and replacement. We’re one of the few manufacturers who have added the option of flow through expansion vessels to our range. These vessels with a Flowjet valve are good practice for all installations but are a particularly sound choice for healthcare premises.

What materials are used in expansion vessels?

The expansion vessel included in our Systempak 3FT – flow through type has a Butyl rubber internal bladder which has less risk of bacteria growth, including Legionella, than EPDM (Ethylene Propylene Diene Monomer) versions. Expansion vessels made from butyl rubber have been proven more effective than other widely used/standard lining materials at preventing the formation of bacteria. A butyl membrane is therefore a lower risk and a safer option. It’s worth noting that an overwhelming number of projects within the healthcare sector are advised as part of the initial project brief not to install any products containing EPDM due to the risks associated with bacterial growth.

Which expansion vessels are available from ACV?

We can provide bespoke unvented kits that include appropriate sized expansion vessels for all our hot water products. We can also offer a flow through expansion vessel and Flowjet valve as part of our Systempak 3FT, helping you to reduce the risk of legionella bacteria breeding in your hot water system.

Talk to us to select the right water heater and unvented kit for your next hot water project.